WMS Explained: Functions and Limitations of Traditional WMS

A warehouse management system (WMS) comprises software and processes that help businesses to control and administer warehouse operations from the point of goods entering the warehouse to their shipping. The purpose is to provide visibility into a business’ inventory and manage supply chain fulfillment from the distribution center to the store shelf.

Additionally, WMS helps companies to optimize their labor and space utilization, and equipment investments by making the best use of resources and material flows.

Main Functions of a WMS:

Inventory Optimization: Tracking stock levels, locations, and movements.

Order Completion: Organizing the picking, packing, and shipping of orders.

Supply Chain Visibility: Offering real-time data on inventory status and order status.

Analytics: Providing reports into the operational efficiency and recommendations for improvement.

Challenges Traditional WMS Systems Face

- Human errors in data entry and inventory tracking

- Inflexibility in adapting to changes in demand/supply disruptions

- Poor visibility into real-time tracking leading to lag in response times

- Limited scalability and inability to keep up with increased demand and complexity

In order to provide customers with the best experience and maintain efficiency in the supply chain, WMS needs automation, real-time tracking, adaptability and better integration with other tools. Custom AI software development can resolve all of these challenges and allow businesses to scale at a desired pace.

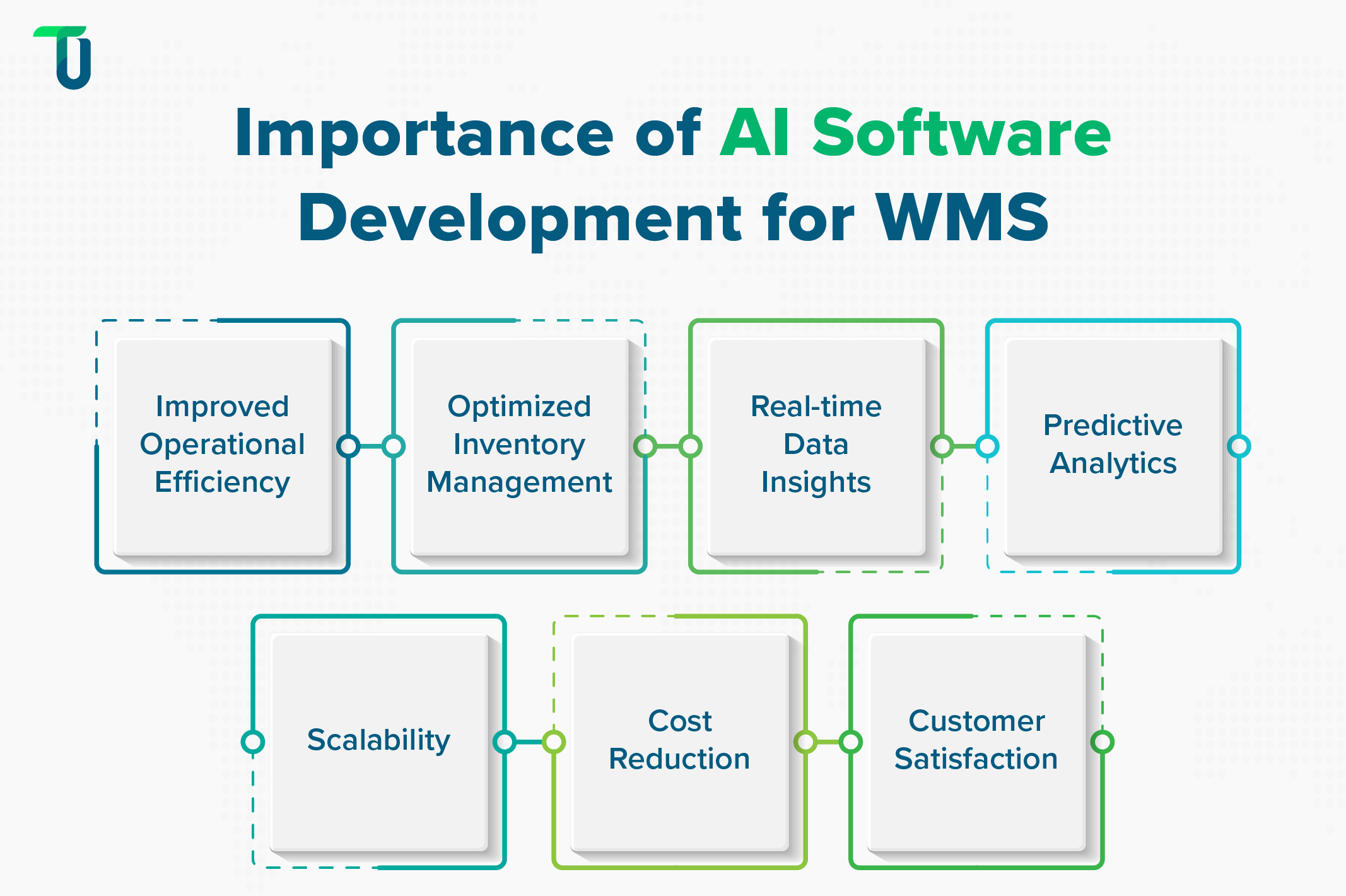

Importance of AI Software Development in Modern Logistics and Warehousing Operations

Adopting AI to improve logistics operations is no longer a nice-to-have option. With custom AI-driven solutions disrupting the way modern warehouses function, here’s why software engineering in Artificial Intelligence is important for logistics and supply chain management companies:

Improved Operational Efficiency: AI-based WMS can automate inventory tracking, order picking, and shipping, leading to faster processing times and fewer errors.

Optimized Inventory Management: AI algorithms can look at historical data and trends to optimize inventory, reducing both overstocking and stockouts.

Real-time Data Insights: By analyzing real-time data, AI-based WMS can help managers make informed and timely decisions with advanced data-driven insights

Predictive Analytics: The use of predictive analytics for maintenance can identify potential equipment failures before they occur, reducing downtime and improving reliability.

Scalability: AI-enabled WMS can easily adapt to increasing data volumes and warehouse operations, ensuring the system remains effective as your business grows.

Cost Reduction: By optimizing operations and reducing errors, AI software development solutions for WMS help lower operational costs and improve profitability.

Customer Satisfaction: AI-led insights help businesses to offer more accurate delivery schedules and tracking of shipments, enhancing customer experience.

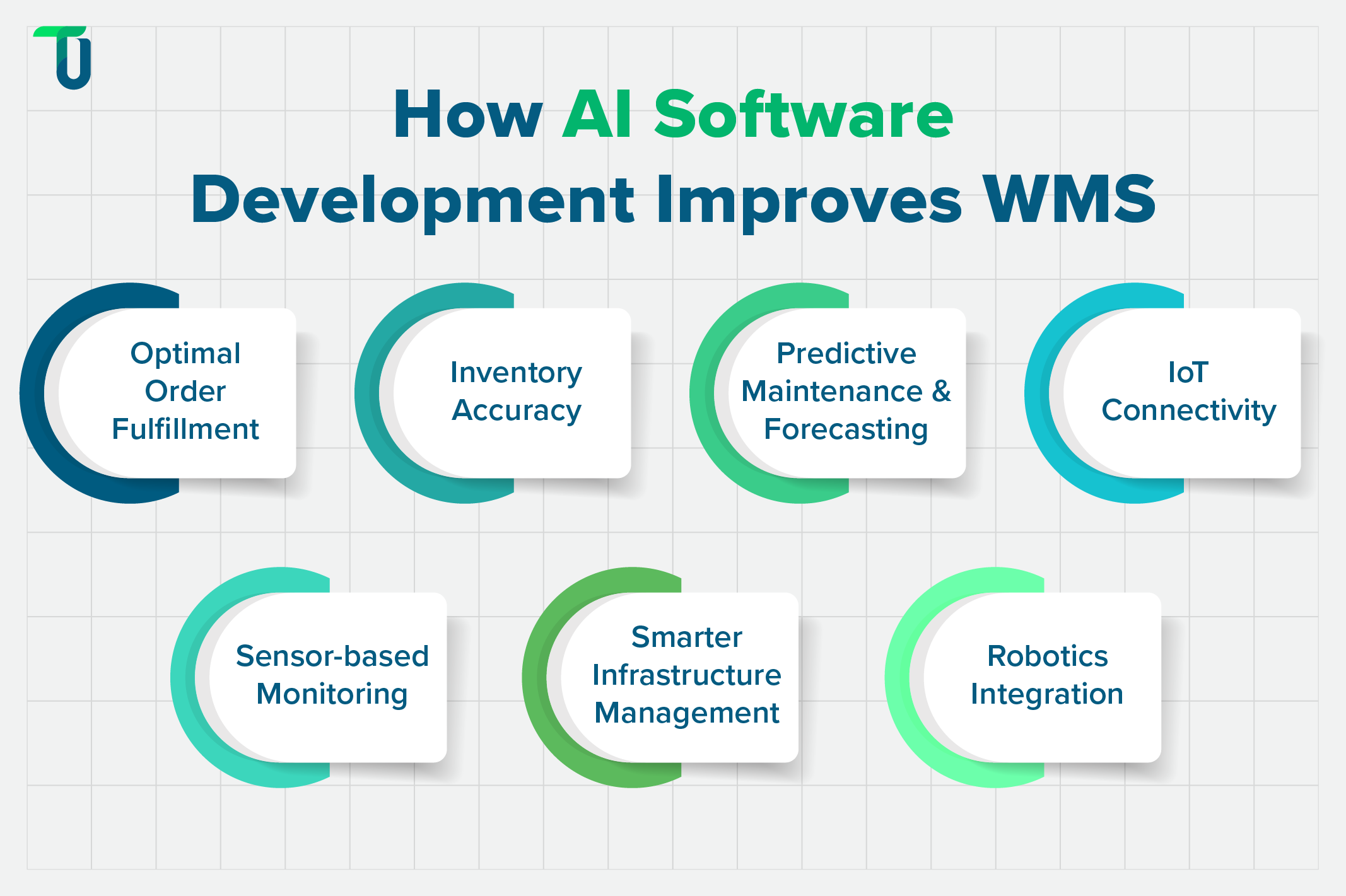

How Does AI Software Development for WMS Help Warehouse Operations

Custom AI software development can help enhance the efficiency, accuracy, and scalability of warehouse operations in the following ways:

Optimal Order Fulfillment: Customer satisfaction is the cornerstone of a market as dynamic and competitive as warehouse management. One of the biggest benefits of AI software development in warehouse management lies in its ability to streamline order fulfillment. By analyzing historical data, predicting demand patterns, and selecting the best picking routes, intelligent algorithms make the entire process streamlined, reducing lead times, and improving customer satisfaction.

Inventory Accuracy: AI-backed systems bring unmatched precision to inventory management. Advanced algorithms and machine learning processes ensure real-time tracking, reducing the error margins and improving the inventory accuracy. This in turn, allows businesses to maintain optimal stock levels and minimize the risk of overstocking or understocking.

Predictive Maintenance and Forecasting: One of the key advantages of using AI processes is the predictive and prescriptive insights that improve operational continuity. Using advanced data analysis, AI predicts risk factors such as equipment failures to schedule maintenance proactively. The approach ensures minimum downtime, optimal continuity, and enhances the flow. AI-backed predictive maintenance and forecasting can not only save thousands of dollars but ensure a resilient warehouse management system.

AI-driven Predictive Maintenance Systems are changing how businesses operate not just in logistics but across industries. Check out our blog on the impact of AI in business to find out their use cases in other industries.

Integration with IoT for Connectivity: The power of AI and the Internet of Things(IoT) combined leads to a comprehensive network of interconnected devices in the warehouse. This allows for real-time communication among various elements, facilitating a seamless workflow. Using technology like smart sensors, RFID tags, etc., this synergy creates a seamless workflow.

Sensor-based Monitoring: An interesting application of AI in warehouse management is the use of sensors for real-time visibility into each aspect of the operation. Sensors track movement of goods, monitor environmental conditions, and even check for suspicious activities. Real-time data helps business owners to make informed decisions, and allows warehouse operators to adapt to changing circumstances quickly.

Smarter Infrastructure Management: AI-powered smart warehousing infrastructure makes optimal use of warehouse space. Algorithms can analyze data on product dimensions, demand trends, and turnover rates to recommend the best storage configurations. This not only enhances space efficiency but also enables faster retrieval, resulting in overall efficiency and agility.

Integration of Robotics for Material Handling: AI-powered robotics are redefining material handling in warehouses. Intelligent AI, armed with computer vision and learning capabilities, can understand the complex warehouse environments. Robotics perform a significant chunk of material handling tasks such as picking, packing, loading, unloading, sorting, and transporting, leading to remarkable improvements in efficiency, accuracy, and speed.

Interested to find out more about AI Software Development Services for WMS?

Our solutions team can help you with the right AI strategy and custom AI development for Warehouse Management Systems.

AI Software Development for WMS: Implementation Challenges and Recommended Solutions

Implementing AI-driven WMS solutions requires careful planning and consideration of several factors

Infrastructure Upgrade for AI Implementation: Implementing AI-based WMS software requires upgrades to the hardware, especially if you are using legacy systems. Depending on your design, you may need IoT devices (sensors, RFID), cloud deployment, or increased on-premise capacity.

To overcome this challenge, carry out AI software development and implementation in a phased manner, focusing on high-impact areas to optimize costs and maximize ROI.

Quality of Data: Warehouses often work with legacy systems or siloed information, making it challenging to bring all the moving parts together and clean up the data for AI applications. Since AI models rely heavily on quality data, poor or inconsistent data can lead to inaccurate forecasts.

Leverage data engineering to ensure the data used for training AI models is high-quality. With data cleaning and integration processes, you can unify the data stored in different systems and improve data accuracy for AI-driven insights.

Employee Training and Navigating Disruption: Any major change to existing systems and workflows often leads to employee resistance and temporary disruptions. Navigate this roadblock by using training as a tool to overcome cultural barriers to digital transformation.

Integration with Legacy Software: You need to ensure interoperability between AI-based solutions and your existing software infrastructure, often requiring legacy modernization and migration, or custom middleware solutions.

AI consultants can help overcome this challenge by assessing your existing IT infrastructure and recommending the right processes and tools to integrate AI-based solutions with your legacy software, typically using APIs or middleware tools.

Monitoring and Optimization: As AI learns with practice, AI-based systems improve their performance over time with continuous monitoring and optimization efforts, requiring dedicated IT support.

Your AI software development partner will provide support to monitor performance, manage updates, and continuously optimize AI models, so you enjoy the benefits of AI implementation faster.

Conclusion: Automate Warehouse Operations with AI Software Development

Warehouse Management Systems are crucial for efficient supply chain management, but existing systems and legacy software often struggle to meet the evolving needs of a competitive marketplace. We’ve already discussed how developing custom AI-based solutions to integrate with your existing WMS can help streamline and automate warehouse operations while reducing costs and improving customer satisfaction.

We, at TenUp, focus on AI software development and tailor our approach to build personalized solutions to overcome the specific challenges your warehouse business faces. Our experienced team of AI developers and solutions architects will ensure the AI solution we build seamlessly integrates with your existing IT infrastructure and provide real results.

Want to explore AI-driven solutions for Warehouse Management Systems?

Our experts can help you craft the right AI strategy and develop custom AI solutions tailored to your WMS needs.

Frequently asked questions

How can software engineering in Artificial Intelligence help with warehouse management?

AI-powered automation improves warehouse management by enhancing operational efficiency, reducing overheads, improving worker safety and materials management. It uses predictive analytics and forecasting to improve safety and flag risks, monitors stocking parameters and speeds up proactive maintenance, ensuring rapid responses to safety standards, and inventory needs. This improves the compliance, safety, and agility of operations, reducing the error margins and resulting in improved customer satisfaction.

What does AI software development for Warehouse Management System (WMS) involve?

Building custom AI solutions and integrating with WMS essentially means including AI algorithms, models, and techniques into your WMS to automate tasks, streamline warehouse management, and improve overall operational efficiency.

How can custom AI software development help reduce operational costs in a warehouse setting?

By leveraging AI capabilities, custom software solutions can optimize task allocation and warehouse layout, automate repetitive tasks, and improve demand forecasting, all of which contribute to reduced labor and operational costs over time.

Are legacy systems compatible with AI software development solutions?

Majority of legacy systems can be upgraded or integrated with AI-based software solutions. However, it often necessitates, middleware or system changes to ensure seamless integration and flow of data.